-

Cutting Pliers 1 x 80.00

Cutting Pliers 1 x 80.00 -

Safety Helmet 1 x $120.00

Safety Helmet 1 x $120.00 -

Jack Hammer Drill 1 x $230.00

Jack Hammer Drill 1 x $230.00

PII CERAMIC MEMBRANE TECHNOLOGY

We have developed the MBBR technology in a way to reduce costing of effluent treatment and to work with an efficiency 98% continuously. We designed with the standard Alpha aluminum ceramic membranes. We have considered the ceramic membrane for this process at last after all types of R & D`s. The success rate of PII ceramic membrane technology is 100%.

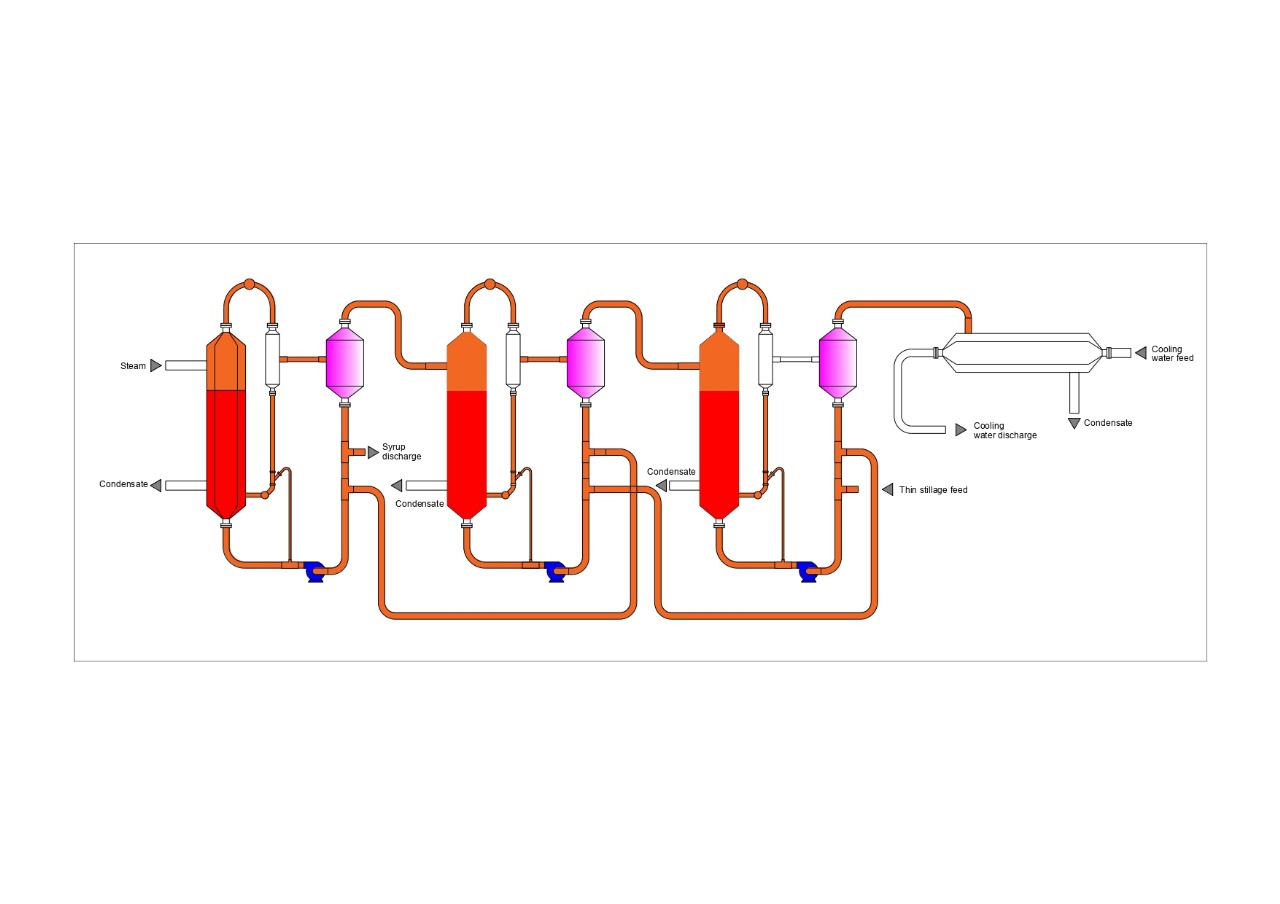

Abstract: Attempts are made to conclude this ceramic membrane technology, there we got a 100% result in all types of industries. After anaerobic and aerobic process, we are suggesting the PII ceramic membrane technology to reduce TDS & TSS by passing the treated effluent through the membrane and make 80% to 85% of recovery. By this we will achieve continuous efficiency and costing will be low.

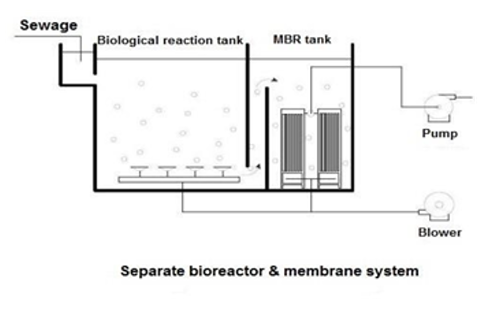

The PII Filtration System (VFS) process is a proven to filtrate sea water method which combines a biological treatment process and a membrane filtration process for final solid-liquid separation. The BFS perfectly eliminates the Clarifier/DAF, Sand Filters/Media Filters and deliver the treated water which will feed to RO systems. The AF303 PII Evaluation Unit is designed for evaluating the separation effect of MBR system.

Use for Municipal water treatment.

Use in pharma and manufacturing industries

High cod/bod waste water treatment

Biological waste treatment.

Effluent treatment from textile and dyeing industries

- Capacity provided:

- According to the requirement PII provide capacity(10KLPD to 2MLD) by considering feed characteristic's.