-

Cutting Pliers 1 x 80.00

Cutting Pliers 1 x 80.00 -

Safety Helmet 1 x $120.00

Safety Helmet 1 x $120.00 -

Jack Hammer Drill 1 x $230.00

Jack Hammer Drill 1 x $230.00

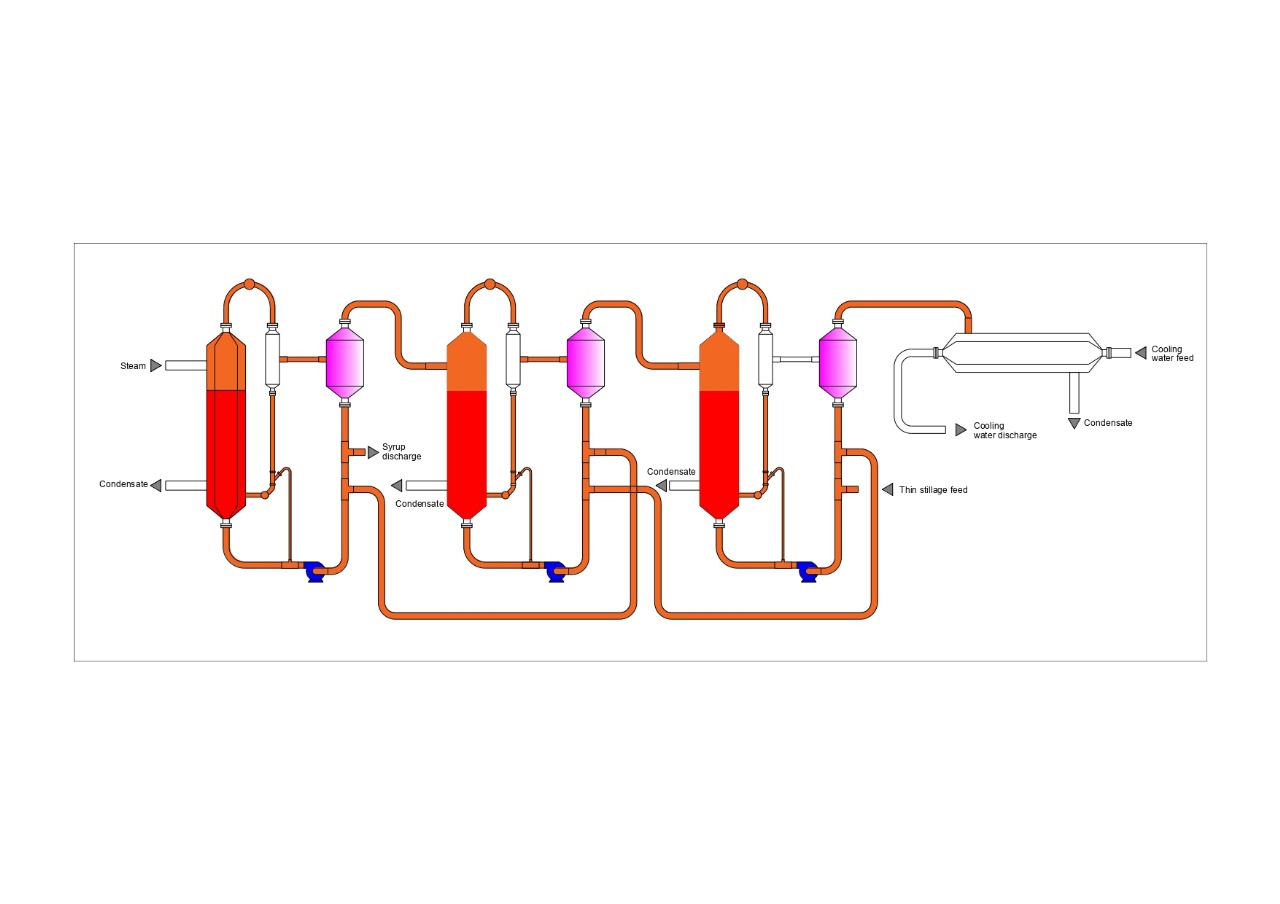

Combined circulation evaporator

The Combined circulation evaporator provides easy unrestricted liquid distribution, eliminates long circulation piping, and either reduces overall head room requirements or reduced circulation rates. There will be partition plate between calandria. The effluent enter into tubes than flow will be counter flow to the steam at the same time it will be parallel flow also the velocity will be lower than forced circulation evaporator system.

The heat transfer takes place in calandria and reach a temperature, passed to the vapor separator and vapor will be separated to another effect or condenser. The separation of the vapor from effluent continuous process, effluent will become high concentrated, than transfer to ATFD for solid output. Vapor become condensation and out as permit with low conductivity.

Key points about Forced Circulation Evaporators (PII FC Evaporators) and their application:

- Depend upon the capacity of water to be evaporated the no of effect can be increase. Combined circulation evaporator will be design for maximum 5 effect. .

- Combined circulation system is operated by the vacuum base, due to this evaporation done in below boiling point of water and for smooth running of plant

- PII CC Evaporator process equipment involved: Calandria, Vapour separator, condenser, condensate vessel and feed tank

- PII Can design of evaporator with thermic fluid, steam, hot water. Other major utilities involved is cooling water, power

- PII Manufacturing range: 5 KLPD to 2 MLD

- PII can manufacturer evaporator with below MOC. MOC selection majorly

depends up on the salt present in the effluent.

- a )SS316

- b) SS304

- c) Duplex

- d) Super duplex

- e) Titanium

- PII can also manufacturer the Evaporator in other MOC also or combination of above given MOC.