-

Cutting Pliers 1 x 80.00

Cutting Pliers 1 x 80.00 -

Safety Helmet 1 x $120.00

Safety Helmet 1 x $120.00 -

Jack Hammer Drill 1 x $230.00

Jack Hammer Drill 1 x $230.00

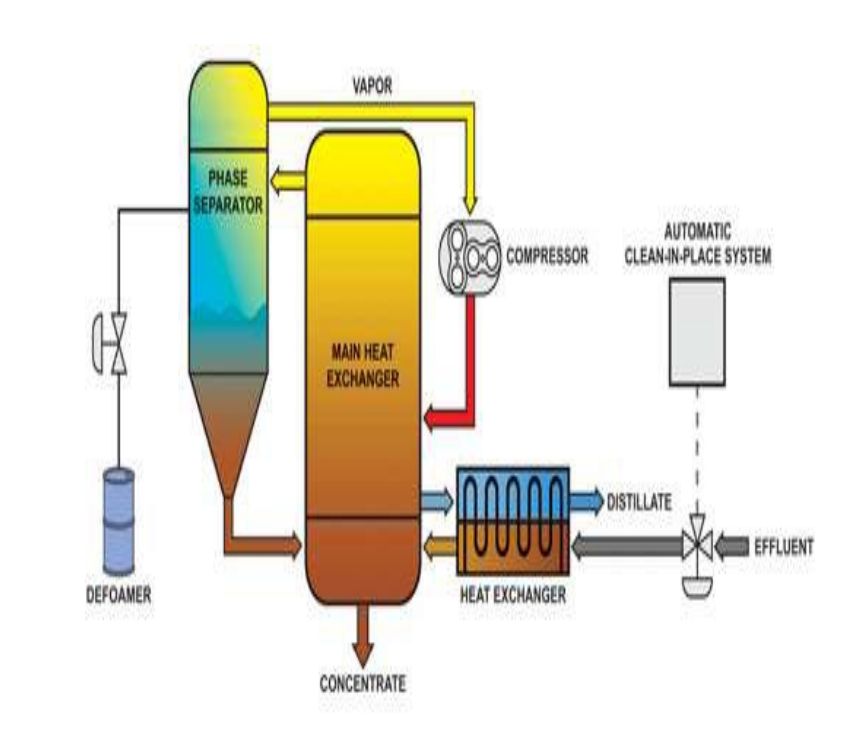

Mechanical Rapour Re-Compressor Evaporator

Mechanical vapour re-compressor technology is the advance evaporation method . We use positive displacement blower or centrifugal blower for re- compression . The heating unit is used boiler, heater or PII technology.

We use PII technology to avoid external heat source to reduce cost of operation . This technology functions same as other evaporator, condensate recovery is collected out and 35% W/W% liquid collected out and feed to ATFD.

Operation cost : Operation cost will be 0.35 Rs per litre, as capacity increases operation cost decreases.

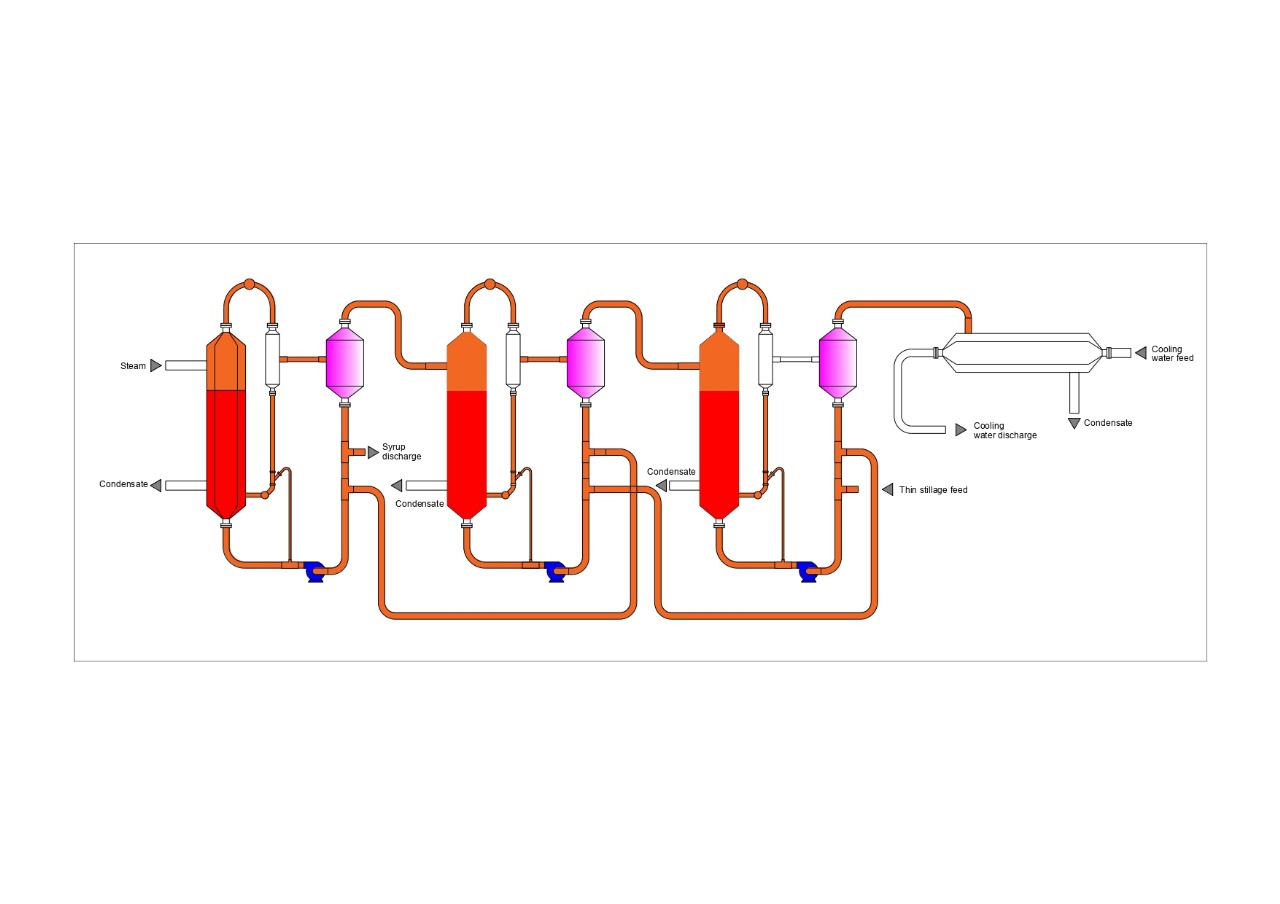

Key points about Forced Circulation Evaporators (PII FC Evaporators) and their application:

- Depend upon the capacity of water to be evaporated the no of effect can be increase. Falling film circulation evaporator will be design for maximum 3 effect. .

- The entire pump used in evaporator is centrifugal with double

- Falling film circulation system is operated by the vacuum base, due to this evaporation done in below boiling point of water and for smooth running of plant

- PII Evaporator process equipment involved: Calandria, Vapour separator, condenser, condensate vessel and feed tank

- PII Can design of evaporator with thermic fluid, steam, hot water. Other major utilities involved is cooling water, power

- PII Manufacturing range: 5 KLPD to 2 MLD

- PII can manufacturer evaporator with below MOC. MOC selection majorly

depends up on the salt present in the effluent.

- a )SS316

- b) SS304

- c) Duplex

- d) Super duplex

- e) Titanium

- PII can also manufacturer the Evaporator in other MOC also or combination of above given MOC.

-

Industries we serve:

1))Pharmaceuticals and drug industries

2)Chemical industries

3)Fertilizers industries

4) AGRO industries