-

Cutting Pliers 1 x 80.00

Cutting Pliers 1 x 80.00 -

Safety Helmet 1 x $120.00

Safety Helmet 1 x $120.00 -

Jack Hammer Drill 1 x $230.00

Jack Hammer Drill 1 x $230.00

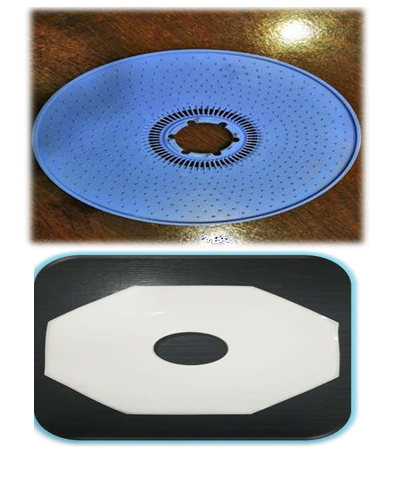

DISC TYPE REVERSE OSMOSIS

DTRO systems are compact in size, flexible in operation and provided with easy access to all membranes for inspection, replacement and other activities. The membranes are installed in a pressure tight case using the central axis and hence the assembly and removal can be done easily and the replacement is very simple. Compare to other similar disc membranes systems available today; DTRO system is equipped with many added advantages.

Abstract: DTRO is a membrane system is designed to ensure molecular and ionic separation for a whole spectrum of pollutants in all environments. DT membranes can separate everything from suspended matter to smallest ions, including colloids, bacteria, viruses, and organic matter and total dissolve solids. The molded ABS spacing discs separating membrane cushions, which are formed from three octagonal layers.

- Minimization of membrane scaling and fouling:

- The DTRO system uses short feed flow path sand high-packing densities to minimize concentration polarization and physical flow impediments. Hence, the scaling and fouling are reduced while high energy efficiency is maintained.

- Increased life of Membrane:

- Due to decrease in fouling and scaling compare to spiral wound membranes, DTRO membranes have longer life.

- BEST Suited Technology for Waste water and Effluent Application:

- The DTRO membranes are able to cop up with high DTI limit and High BOD/COD contents and hence the system can be operated with very minimal pre-treatment.

- Savings in membrane replacement cost:

- Spiral wound membranes are sealed and elements to be replaced completely. DTRO membranes can be replaced as individual sheets thereby saving.

- Easy access to all membranes:

- DTRO system can be opened and closed easily for inspection replacement and other activities.

- No special skill required:

- The DTRO system is static and no special skill are required to operate the system.

- Compact and flexible:

- A DTRO system simplifies transportation and installation and enable efficiency use of floor space. Low energy consumption: DTRO system have less power consumption.

- Easy and superior cleaning behaviour:

- The DTRO system employs simple cleaning procedure due to less fouling and scaling of membranes.

- Leachate water treatment

- Effluent treatment API, formulation plant & combined effluent from pharmaceuticals industry

- Picking & oily waste treatment in steel industry.

- Metal recovery waste recycle.

- Tannery effluent treatment & recycling.

- High cod/bod waste water treatment.

- Backwash recovery and recycling.

- Treatment and re use of leachate from landfills

- Effluent treatment from textile and dyeing industries.

- Common and combined effluent treatment.

- Recycling of spend wash and bio machination.

- Reject treatment from spiral RO plant.

- DM plant waste recycling.

- Hazardous chemical wastewater recycling.