-

Cutting Pliers 1 x 80.00

Cutting Pliers 1 x 80.00 -

Safety Helmet 1 x $120.00

Safety Helmet 1 x $120.00 -

Jack Hammer Drill 1 x $230.00

Jack Hammer Drill 1 x $230.00

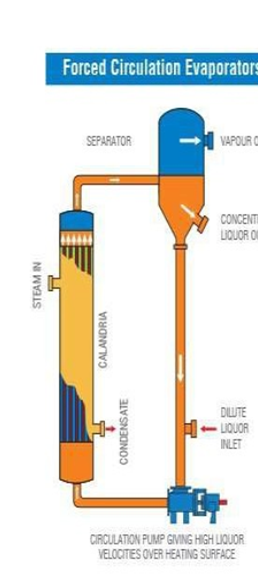

Forced Circulation Evaporator

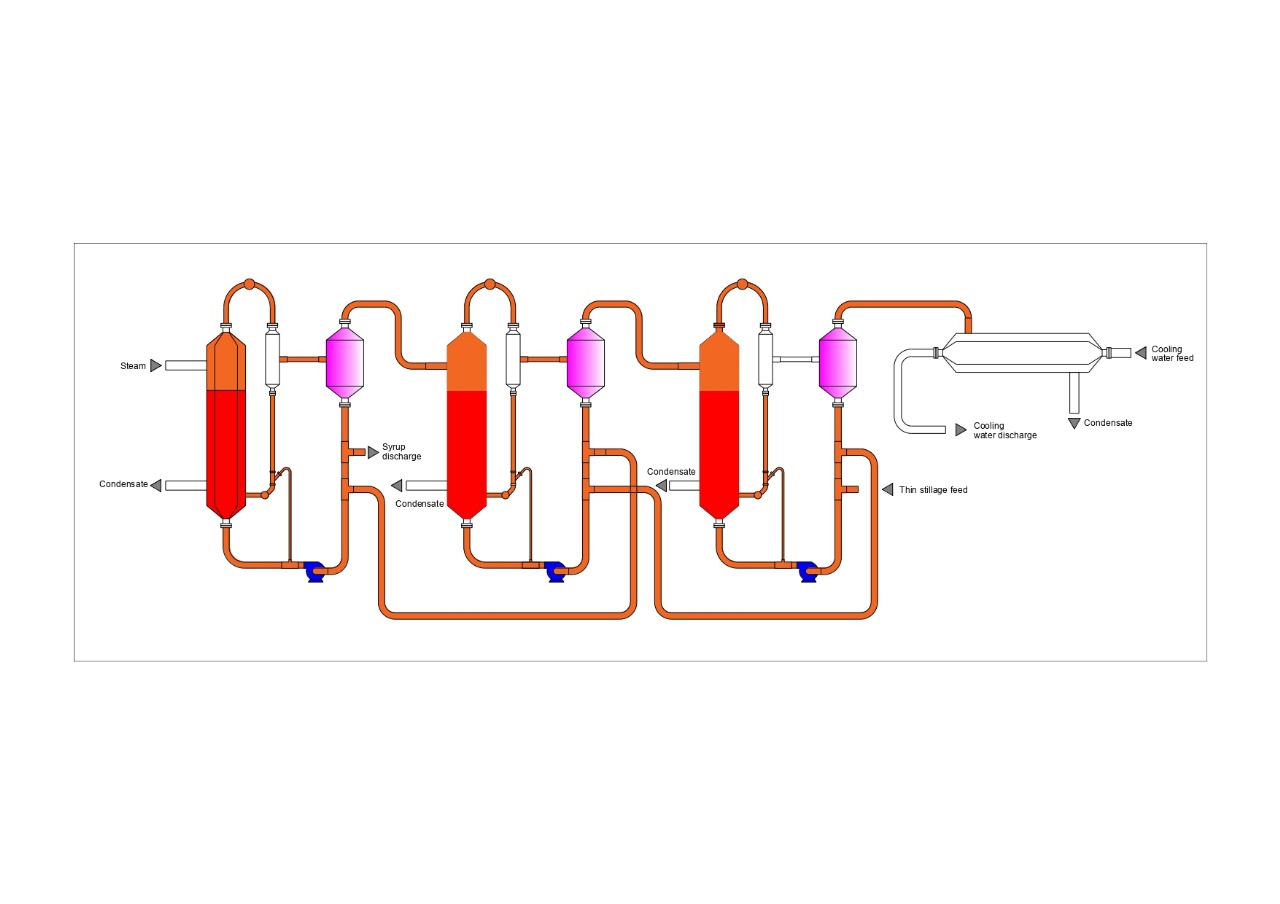

Forced circulation evaporators are known for their extended operational efficiency, making them a suitable choice for handling some of the most challenging process fluids. They exhibit higher fluid velocities within their tubes when compared to combined and falling film evaporators. In this system, the effluent enters the tubes, and the flow becomes counter to the steam's direction. Heat transfer occurs in the calandria, raising the temperature before the vapor is directed to a vapor separator for further separation in subsequent effects or condensation.

This continuous vapor separation process results in a highly concentrated effluent, which is then transferred to an Agitated Thin Film Dryer (ATFD) for solid output. The vapor undergoes condensation and is released with low conductivity. The forced circulation system operates under vacuum conditions, allowing for evaporation below the boiling point of water and ensuring the smooth operation of the plant.

Key points about Forced Circulation Evaporators (PII FC Evaporators) and their application:

- The number of effects in a forced circulation evaporator can be increased based on the required water evaporation capacity, typically designed for a maximum of 5 effects.

- Centrifugal pumps with double mechanical seals are used in the evaporator, and for high-capacity recirculation, axial flow pumps are chosen.

- The system operates under vacuum conditions to enable evaporation below the boiling point of water, ensuring plant efficiency.

- Key components involved in the PII FC Evaporator process equipment include the calandria, vapor separator, condenser, condensate vessel, and feed tank.

- PII can design evaporators to work with various heating sources such as thermic fluid, steam, or hot water. Other major utilities required include cooling water and power.

- PII's manufacturing range for evaporators spans from 5 KLPD to 2 MLD (Kiloliters Per Day to Megaliters Per Day).

- The choice of material of construction (MOC) for the evaporator is typically determined by the salt content present in the effluent and may include options such as SS316, SS304, Duplex, Super Duplex, or Titanium. PII can also customize evaporators using a combination of these MOCs or other materials as needed.